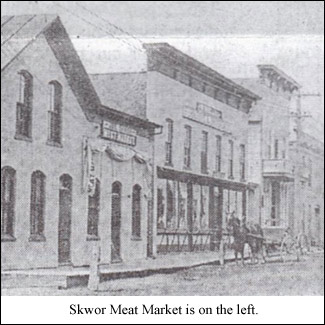

The Skwor Meat Market

Skwor's Meat Market, 326 East main Street in Mishicot, dates back to 1879 when Adolph Grim deeded the building to Louis Levenhagen. This was the original meat market, appearing much the same as it is now, more than a century later. in 1894, Levenhagen deeded the market to Joseph Skwor. Joseph, and his wife Rose, working together, built the business. Rose helped where needed. A petite but strong woman, she could carry a quarter of beef on her shoulder to where it would be trimmed into special cuts of meat. Joseph and Rose continued in business until their two sons, Charles and Hugo, joined in the business. It then became known as Jos. Skwor and Sons Meats.

When Joseph semi-retired, Charles and Hugo entered into a partnership, and a new sign over the door said "Skwor Bros. Meat Market." In 1939, Charles moved to Milwaukee and sold his half of the business to Hugo. It then became "Skwor Meat Market." Paul, son of Hugo, helped him, along with hired help. They bought livestock, butchered, retailed meat, and made ring bologna, liver sausage, blood sausage, summer sausage, sultz, wieners and bratwurst from Bohemian and Polish recipes handed down in the family. They cured and smoked their own hams and bacon. Joseph would walk down to the market every day to help. His home was about two blocks away. People would stand in line waiting for "Joe" to wait on them, as he would frequently forget the latest price and charge them for meats at the old, lower price.

When Joseph semi-retired, Charles and Hugo entered into a partnership, and a new sign over the door said "Skwor Bros. Meat Market." In 1939, Charles moved to Milwaukee and sold his half of the business to Hugo. It then became "Skwor Meat Market." Paul, son of Hugo, helped him, along with hired help. They bought livestock, butchered, retailed meat, and made ring bologna, liver sausage, blood sausage, summer sausage, sultz, wieners and bratwurst from Bohemian and Polish recipes handed down in the family. They cured and smoked their own hams and bacon. Joseph would walk down to the market every day to help. His home was about two blocks away. People would stand in line waiting for "Joe" to wait on them, as he would frequently forget the latest price and charge them for meats at the old, lower price.

Joseph, Charles and Hugo could converse in Polish and Bohemian with the early settlers. In the early days, sawdust was used to cover the floor where the customers stood, to keep the floor clean and for fragrance. When mothers brought their young children into the shop, Joseph or Hugo would give them a wiener to eat.

Before electrical refrigeration was invented, Skwor Meats used large chunks of ice to cool meat and keep it from spoiling. Hugo invented a gasoline-engine-powered saw which would cut ice from the nearby West Twin River, when it was frozen the thickest, usually between the holidays of Christmas and the New Year. The blocks were about 18 x 36 inches, and several men helped load them into a truck bed to be hauled to the ice house, located near the market. Here they were covered with sawdust to keep them from melting. They cut enough ice for their own needs for a whole year as well as selling it to customers for their ice boxes. After electric refrigerators were available, the ice business was no longer needed.

Hugo built insulated containers which fit onto a pick-up truck with blocks of ice which was used to keep the meat cool. Both Hugo and Charles traveled regular routes throughout the county to bring their meat products to the farmers. As children, we liked to go along with our dads to keep them company during the five-hour trip. It was usually a very busy time for the farmers, and they appreciated having their meat brought to them.

During the springs, the river in Mishicot would flood, and some years the water came over the banks onto the Main Street, running through the building and filling the basement of the meat market. Everything was shut down, to prevent a fire or explosion, until the water subsided. Since that time, a new dam has been built to help regulate the level of the water.

In the 1950's, Hugo Skwor gradually taught his son IPaul the business, and when Hugo retired in 1961, he sold the meat market to Paul and Laverne Skwor. Paul made many improvements in the building and in; areas of meat processing. He built a new smoke house, and people from many miles away would come to buy Skwor's "Ho-Made" sausage. Skwors had their own spice recipe, developed over the years. It was never written down. As youngsters, Victoria and Lois would stop after school to watch Grandpa and Dad make sausage and wieners.

After the meat was ground and the spices added, it was stuffed into natural animal casings, twisted and tied, and loaded onto cars which held rows of the raw products. When the cart was full, they were pushed to another room, and lowered into a huge boiler of hot water. When they had cooked for about the right time, as the girls remember, Grandpa Joseph would fish a sausage out, holding it up to his ear and squeezing it. If it sounded "like a bullfrog," he would toss it back to cook some more.

Since 1959, meat of USDA quality was purchased in quarters from nearby meat packing houses in Green Bay and Milwaukee. Slaughtering was no longer done at Mishicot. At the end of each day, the wooden chopping blocks were scraped and salted, and the saws and knives sharpened, cleaned, and put away, ready for the next day's business.

They cured and smoked their own hams, sausage, and bacon. While the smokehouse was being used, Paul got little sleep, because the fire had to be checked every fifteen minutes. Smoking was done the old-fashioned way, using sweet maple wood. Paul could smell if the fire was too hot or too low from three rooms away. Water was kept handy, and some was poured in to keep the humidity just right. Smoking of hams usually took three days. Summer sausage, bacon, wieners, and bologna were smoked once a week, and were always all sold out before the next batch was made.

Paul operated the business until November 23, 1984, when he suddenly passed away of a heart attack. The business was carried on by David and Laverne, Paul's son and widow. Laverne, fondly known as Susie, worked with David in the market, waiting on customers and tying wieners and sausages. They operated the business for six years, until 1991 ... just three years shy of Skwor Meats' 100th anniversary.

(Edited by: George Schmidt)

Return to List of Articles